Product Features:

·Rated Voltage: 600/1000V

·Rated Temperature: -60 ℃ to +180 ℃

·the highest temperature to use: +230℃

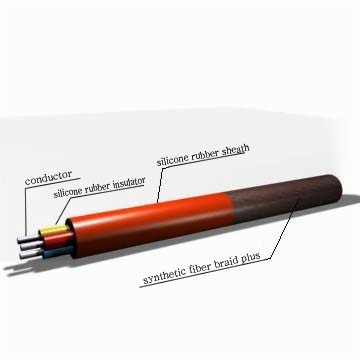

·Conductors: bare brass or tin-coated copper

·Insulator: Silicone Rubber

·sheath: Silicone Rubber

·jacket: synthetic fiber braid plus

|

ITEMS |

Technical Datas |

Applied Standard |

|

appearance |

Smooth even without loose |

DIN VDE 0250-502

DIN VDE 0282-1:1999.01

DIN VDE 0282-2:1999.01

Q/320281ANX01-2006 |

|

Spark test |

AC6KV/ 0.15 S |

|

Vol. test |

3 KV/5 min |

|

insulation

sheath

mechanical

character |

Before aging |

Tensile strength |

≥5.0N/mm² |

|

Break elongation rate |

≥150% |

|

After aging |

Tensile strength |

≥4.0N/mm² |

|

Break elongation rate |

≥120% |

|

harmful substance control |

COMPLY WITH ROHS |

EU—2002/95/EC |

|

YGZ-GS① |

|

|

core No.×section |

structure |

insualtion |

sheath |

wire OD |

conductor resistance 20℃ Ω/KM |

|

thickness |

OD |

thickness |

OD |

thickness of the braid |

nominal diameter |

allowance |

|

mm² |

No./diameter mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

brass |

tin-coat |

|

2×1.5 |

30/0.25 |

0.6 |

2.9 |

1.0 |

7.8 |

0.6 |

9.0 |

±0.60 |

13.3 |

13.7 |

|

3×1.5 |

30/0.25 |

0.6 |

2.9 |

1.0 |

8.3 |

0.6 |

9.5 |

±0.60 |

13.3 |

13.7 |

|

4×1.5 |

30/0.25 |

0.6 |

2.9 |

1.0 |

9.0 |

0.6 |

10.2 |

±0.60 |

13.3 |

13.7 |

|

5×1.5 |

30/0.25 |

0.6 |

2.9 |

1.1 |

10.0 |

0.6 |

11.2 |

±0.60 |

13.3 |

13.7 |

|

6×1.5 |

30/0.25 |

0.6 |

2.9 |

1.1 |

10.4 |

0.6 |

11.6 |

±0.60 |

13.3 |

13.7 |

|

7×1.5 |

30/0.25 |

0.6 |

2.9 |

1.1 |

10.9 |

0.6 |

12.1 |

±0.60 |

13.3 |

13.7 |

|

10×1.5 |

30/0.25 |

0.6 |

2.9 |

1.2 |

14.0 |

0.6 |

15.2 |

±0.70 |

13.3 |

13.7 |

|

12×1.5 |

30/0.25 |

0.6 |

2.9 |

1.4 |

14.9 |

0.6 |

16.1 |

±0.70 |

13.3 |

13.7 |

|

14×1.5 |

30/0.25 |

0.6 |

2.9 |

1.4 |

15.7 |

0.6 |

16.9 |

±0.70 |

13.3 |

13.7 |

|

16×1.5 |

30/0.25 |

0.6 |

2.9 |

1.4 |

16.6 |

0.6 |

17.8 |

±0.70 |

13.3 |

13.7 |

|

18×1.5 |

30/0.25 |

0.6 |

2.9 |

1.6 |

17.2 |

0.6 |

18.4 |

±0.70 |

13.3 |

13.7 |

|

19×1.5 |

30/0.25 |

0.6 |

2.9 |

1.6 |

17.7 |

0.6 |

18.9 |

±0.80 |

13.3 |

13.7 |

|

20×1.5 |

30/0.25 |

0.6 |

2.9 |

1.8 |

18.4 |

0.6 |

19.6 |

±0.80 |

13.3 |

13.7 |

|

24×1.5 |

30/0.25 |

0.6 |

2.9 |

1.8 |

21.0 |

0.8 |

22.6 |

±0.80 |

13.3 |

13.7 |

|

27×1.5 |

30/0.25 |

0.6 |

2.9 |

2.0 |

22.0 |

0.8 |

23.6 |

±0.80 |

13.3 |

13.7 |

|

37×1.5 |

30/0.25 |

0.6 |

2.9 |

2.4 |

25.2 |

0.8 |

26.8 |

±1.0 |

13.3 |

13.7 |

|

2×2.5 |

50/0.25 |

0.7 |

3.4 |

1.2 |

9.2 |

0.6 |

10.4 |

±0.60 |

7.98 |

8.21 |

|

3×2.5 |

50/0.25 |

0.7 |

3.4 |

1.2 |

9.8 |

0.6 |

11.0 |

±0.60 |

7.98 |

8.21 |

|

4×2.5 |

50/0.25 |

0.7 |

3.4 |

1.2 |

10.6 |

0.6 |

11.8 |

±0.60 |

7.98 |

8.21 |

|

5×2.5 |

50/0.25 |

0.7 |

3.4 |

1.2 |

11.6 |

0.6 |

12.8 |

±0.60 |

7.98 |

8.21 |

|

6×2.5 |

50/0.25 |

0.7 |

3.4 |

1.2 |

12.0 |

0.6 |

13.2 |

±0.60 |

7.98 |

8.21 |

|

7×2.5 |

50/0.25 |

0.7 |

3.4 |

1.2 |

12.6 |

0.6 |

13.8 |

±0.60 |

7.98 |

8.21 |

|

10×2.5 |

50/0.25 |

0.7 |

3.4 |

1.4 |

16.4 |

0.6 |

17.6 |

±0.70 |

7.98 |

8.21 |

|

12×2.5 |

50/0.25 |

0.7 |

3.4 |

1.6 |

17.4 |

0.6 |

18.6 |

±0.70 |

7.98 |

8.21 |

|

19×2.5 |

50/0.25 |

0.7 |

3.4 |

1.8 |

20.6 |

0.8 |

22.2 |

±0.80 |

7.98 |

8.21 |

|

24×2.5 |

50/0.25 |

0.7 |

3.4 |

2.2 |

25.0 |

0.8 |

26.6 |

±1.0 |

7.98 |

8.21 |

|

27×2.5 |

50/0.25 |

0.7 |

3.4 |

2.4 |

25.9 |

0.8 |

27.5 |

±1.20 |

7.98 |

8.21 |

|

37×2.5 |

50/0.25 |

0.7 |

3.4 |

2.4 |

28.8 |

0.8 |

30.4 |

±1.20 |

7.98 |

8.21 |

|

YGZ-GS② |

|

|

core No.×section |

structure |

insulation |

sheath |

wire OD |

conductor resistance 20℃ Ω/KM |

|

thickness |

OD |

thickness |

OD |

thickness of the braid |

nominal diameter |

allowance |

|

mm² |

No./diameter mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

brass |

tin-coated |

|

2×4 |

56/0.30 |

0.8 |

4.3 |

1.2 |

11.2 |

0.6 |

12.4 |

±0.60 |

4.95 |

5.09 |

|

3×4 |

56/0.30 |

0.8 |

4.3 |

1.3 |

12.0 |

0.6 |

13.2 |

±0.60 |

4.95 |

5.09 |

|

4×4 |

56/0.30 |

0.8 |

4.3 |

1.5 |

13.5 |

0.6 |

14.7 |

±0.70 |

4.95 |

5.09 |

|

5×4 |

56/0.30 |

0.8 |

4.3 |

1.5 |

14.8 |

0.6 |

16.0 |

±0.70 |

4.95 |

5.09 |

|

6×4 |

56/0.30 |

0.8 |

4.3 |

1.8 |

15.7 |

0.6 |

16.9 |

±0.70 |

4.95 |

5.09 |

|

7×4 |

56/0.30 |

0.8 |

4.3 |

1.8 |

16.6 |

0.6 |

17.8 |

±0.70 |

4.95 |

5.09 |

|

12×4 |

56/0.30 |

0.8 |

4.3 |

2.2 |

22.4 |

0.8 |

24.0 |

±0.80 |

4.95 |

5.09 |

|

2×6 |

84/0.30 |

0.8 |

4.9 |

1.5 |

13.0 |

0.6 |

14.2 |

±0.70 |

3.30 |

3.39 |

|

3×6 |

84/0.30 |

0.8 |

4.9 |

1.5 |

13.7 |

0.6 |

14.9 |

±0.70 |

3.30 |

3.39 |

|

4×6 |

84/0.30 |

0.8 |

4.9 |

1.8 |

15.6 |

0.6 |

16.8 |

±0.70 |

3.30 |

3.39 |

|

5×6 |

84/0.30 |

0.8 |

4.9 |

1.8 |

17.0 |

0.6 |

18.2 |

±0.70 |

3.30 |

3.39 |

|

6×6 |

84/0.30 |

0.8 |

4.9 |

2.0 |

18.0 |

0.6 |

19.2 |

±0.70 |

3.30 |

3.39 |

|

7×6 |

84/0.30 |

0.8 |

4.9 |

2.0 |

18.8 |

0.6 |

20.0 |

±0.80 |

3.30 |

3.39 |

|

2×10 |

84/0.40 |

1.0 |

6.6 |

1.8 |

17.0 |

0.6 |

18.2 |

±0.70 |

1.91 |

1.95 |

|

3×10 |

84/0.40 |

1.0 |

6.6 |

2.0 |

18.4 |

0.6 |

19.6 |

±0.80 |

1.91 |

1.95 |

|

4×10 |

84/0.40 |

1.0 |

6.6 |

2.2 |

20.6 |

0.8 |

22.2 |

±0.80 |

1.91 |

1.95 |

|

5×10 |

84/0.40 |

1.0 |

6.6 |

2.4 |

22.8 |

0.8 |

24.4 |

±0.80 |

1.91 |

1.95 |

|

2×16 |

126/0.40 |

1.2 |

8.2 |

2.0 |

22.6 |

0.8 |

24.2 |

±0.80 |

1.21 |

1.24 |

|

3×16 |

126/0.40 |

1.2 |

8.2 |

2.2 |

22.4 |

0.8 |

24.0 |

±0.80 |

1.21 |

1.24 |

|

4×16 |

126/0.40 |

1.2 |

8.2 |

2.4 |

25.0 |

0.8 |

26.6 |

±1.0 |

1.21 |

1.24 |

|

5×16 |

126/0.40 |

1.2 |

8.2 |

2.6 |

27.6 |

0.8 |

29.2 |

±1.20 |

1.21 |

1.24 |

|

2×25 |

196/0.40 |

1.4 |

10.1 |

2.2 |

25.0 |

0.8 |

26.6 |

±1.0 |

0.78 |

0.795 |

|

3×25 |

196/0.40 |

1.4 |

10.1 |

2.4 |

27.0 |

0.8 |

28.6 |

±1.20 |

0.78 |

0.795 |

|

4×25 |

196/0.40 |

1.4 |

10.1 |

2.4 |

29.5 |

0.8 |

31.1 |

±1.20 |

0.78 |

0.795 |

|

5×25 |

196/0.40 |

1.4 |

10.1 |

2.6 |

32.8 |

1.0 |

34.8 |

±1.20 |

0.78 |

0.795 |

|

2×35 |

276/0.40 |

1.4 |

11.4 |

2.4 |

28.0 |

0.8 |

29.6 |

±1.20 |

0.554 |

0.565 |

|

3×35 |

276/0.40 |

1.4 |

11.4 |

2.6 |

30.0 |

1.0 |

32.0 |

±1.20 |

0.554 |

0.565 |

|

4×35 |

276/0.40 |

1.4 |

11.4 |

2.6 |

33.0 |

1.0 |

35.0 |

±1.20 |

0.554 |

0.565 | |