|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TEL: 852- 211644409

E-mail:wilson2103@163.com

ADD:6/F, Hang Pont Commercial Building, 31 Tonkin Street, Cheung Sha Wan, Kowloon, Hong Kong

|

|

|

|

|

|

|

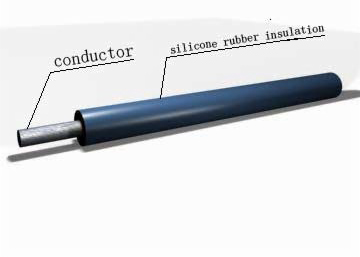

| AWM3134 silicone rubber heat resisting wire |

Product Features:

·Rated Voltage:600V

·Rated temperature:-60℃~+150℃

·Conductor: nickel-coated, tin-coated and silver-coated copper wire

·Insulator: silicone rubber

·Applicable for electron, electrical household appliance, lamps and lanterns, and the internal high temperature environment of combustion equipment

Wire Lettering:

UL AWM3134(18AWG~12AWG) 150℃ 600V I/A CUL AWM 150℃ 600V

|

Items |

Technical datas |

Applied standard |

|

Outer appearance |

Smooth, even, without loose |

UL 758

UL 62

UL 1581 |

|

Spark test |

AC6KV/ 0.15 S |

|

Vol. test |

2 KV/1 min |

|

Insulation resistance |

≥30.5MΩ.KM |

|

mechanical properties of insulation material |

Before aging |

Tensile strength |

≥3.45N/mm² |

|

elongation at break |

≥100% |

|

After aging

(158±1℃×1440h) |

Tensile strength |

60% of the tensile strength before aging |

|

elongation at break |

25% of the elongation before aging |

|

Poisonous substance control |

Comply with ROHS rule |

EU—2002/95/EC |

|

AWG |

conductor |

insulation |

wire OD |

conductor resistance |

|

section |

structure |

diameter |

nominal thick |

min. thick |

nominal |

allowance |

20℃ |

|

NO. |

mm² |

No./mm |

mm |

mm |

mm |

mm |

mm |

Ω/KM |

|

18 |

0.823 |

7/0.39 16/0.26 |

1.20 |

0.80 |

0.72 |

2.80 |

±0.15 |

21.8 |

|

16 |

1.31 |

7/0.49 |

1.47 |

0.80 |

0.72 |

3.10 |

±0.15 |

13.7 |

|

26/0.26 |

1.55 |

0.80 |

0.72 |

3.15 |

|

14 |

2.08 |

7/0.62 41/0.254 |

1.90 |

0.80 |

0.72 |

3.50 |

±0.20 |

8.62 |

|

12 |

3.31 |

19/0.49 43/0.32 |

2.50 |

0.80 |

0.72 |

4.10 |

±0.20 |

5.38 |

|

18 |

0.823 |

1/1.03 |

1.03 |

0.80 |

0.72 |

2.65 |

±0.15 |

21.4 |

|

16 |

1.31 |

1/1.30 |

1.30 |

0.80 |

0.72 |

2.90 |

±0.15 |

13.5 |

|

AWG |

section |

conductor |

insulation |

wire OD |

conductor resistance |

|

structure |

diameter |

nominal thick |

min. thick |

nominal |

allowance |

20℃ |

|

NO. |

mm² |

No./mm |

mm |

mm |

mm |

mm |

mm |

Ω/KM |

|

24 |

0.20 |

12/0.15 |

0.60 |

0.80 |

0.72 |

2.20 |

±0.10 |

93 |

|

22 |

0.30 |

17/0.15 12/0.18 |

0.75 |

0.80 |

0.72 |

2.35 |

±0.10 |

71.2 |

|

20 |

0.50 |

28/0.15 20/0.18 |

0.95 |

0.80 |

0.72 |

2.55 |

±0.10 |

40.1 |

|

18 |

0.75 |

24/0.20 30/0.18 |

1.15 |

0.80 |

0.72 |

2.75 |

±0.15 |

26.7 |

|

17 |

1.0 |

32/0.20 40/0.18 |

1.34 |

0.80 |

0.72 |

2.95 |

±0.15 |

20.0 |

|

16 |

1.25 |

40/0.20 50/0.18 |

1.50 |

0.80 |

0.72 |

3.10 |

±0.15 |

15.9 |

|

15 |

1.50 |

30/0.25 28/0.26 |

1.60 |

0.80 |

0.72 |

3.20 |

±0.20 |

13.7 | |

| |

|

| |

|

|

| |

|

Copyright (c) 2010 Orient Star International Group (HK) Ltd.

苏ICP备10063250号 TEL: 852- 211644409 E-mail: wilson2103@163.com

Add:6/F, Hang Pont Commercial Building, 31 Tonkin Street, Cheung Sha Wan, Kowloon, Hong Kong |

|