|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TEL: 852- 211644409

E-mail:wilson2103@163.com

ADD:6/F, Hang Pont Commercial Building, 31 Tonkin Street, Cheung Sha Wan, Kowloon, Hong Kong

|

|

|

|

|

|

|

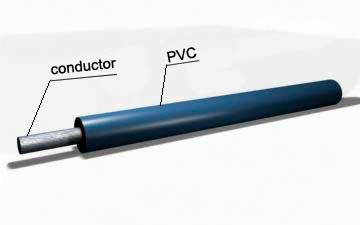

| AWM 1007 PVC Insulation Wire |

Product Features

·Rated Voltage:300V

·Rated temperature:60℃/80℃

·Conductor: bare brass,tin-coated or silver-coated copper wire

·Insulator: PVC

Wire Lettering:

AWM1007(32AWG~16AWG)60℃/80℃ 300V VW-1 CUL AWM I A 60℃/80℃ 300V FT1

|

Items |

Technical datas |

Applied standard |

|

Outer appearance |

Smooth, even |

UL 758

UL 62

UL 1581 |

|

Spark test |

AC3KV/ 0.15 S |

|

Vol. test |

2 KV/1 min |

|

mechanical properties of insulation material |

Before aging |

Tensile strength |

≥10.3N/mm² |

|

elongation at break |

≥100% |

|

After aging

60℃ (100±1℃×240h) 80℃ (121±1℃×168h) |

Tensile strength |

70% of the tensile strength before aging |

|

elongation at break |

45% of the elongation before aging |

|

Poisonous substance control |

Comply with ROHS rule |

EU—2002/95/EC |

|

AWM 1007 80℃ 300V |

|

AWG

No. |

section |

conductor |

insulation |

Wire OD |

conductor resistance 20℃ |

|

structure |

Dia. |

nominal thick |

Min. thick |

nominal |

allowance |

|

mm² |

NO./mm |

mm |

mm |

mm |

mm |

mm |

Ω/KM |

|

32 |

0.0324 |

5/0.10 |

0.3 |

0.39 |

0.33 |

1.08 |

±0.10 |

381 |

|

31 |

0.0401 |

6/0.10 |

0.3 |

0.39 |

0.33 |

1.08 |

±0.10 |

381 |

|

30 |

0.0507 |

7/0.10 |

0.3 |

0.39 |

0.33 |

1.08 |

±0.10 |

381 |

|

29 |

0.0647 |

9/0.10 |

0.35 |

0.39 |

0.33 |

1.13 |

±0.10 |

297 |

|

28 |

0.0804 |

11/0.10 |

0.40 |

0.39 |

0.33 |

1.18 |

±0.10 |

239 |

|

27 |

0.102 |

13/0.10 |

0.43 |

0.39 |

0.33 |

1.21 |

±0.10 |

199 |

|

26 |

0.128 |

7/0.16 |

0.48 |

0.39 |

0.33 |

1.26 |

±0.10 |

188 |

|

25 |

0.162 |

9/0.16 |

0.56 |

0.39 |

0.33 |

1.34 |

±0.10 |

150 |

|

24 |

0.205 |

7/0.20 11/0.16 12/0.15 |

0.60 |

0.39 |

0.33 |

1.38 |

±0.10 |

94.2 |

|

23 |

0.259 |

11/0.18 |

0.70 |

0.39 |

0.33 |

1.48 |

±0.10 |

74., 5 |

|

22 |

0.324 |

13/0.18 7/0.25 17/0.15 |

0.75 |

0.39 |

0.33 |

1.53 |

±0.10 |

59.4 |

|

21 |

0.412 |

17/0.18 |

0.88 |

0.39 |

0.33 |

1.66 |

±0.10 |

46.9 |

|

20 |

0.519 |

21/0.18 10/0.254 26/0.16 7/0.31 |

0.96 |

0.39 |

0.33 |

1.74 |

±0.10 |

36.7 |

|

19 |

0.653 |

26/0.18 |

1.10 |

0.39 |

0.33 |

1.89 |

±0.10 |

29.1 |

|

18 |

0.823 |

33/0.18 16/0.254 7/0.39 24/0.20 |

1.20 |

0.39 |

0.33 |

1.99 |

±0.10 |

23.2 |

|

17 |

1.04 |

21/0.254 40/0.18 32/0.20 |

1.38 |

0.39 |

0.33 |

2.17 |

±0.10 |

18.3 |

|

16 |

1.31 |

26/0.254 7/0.49 52/0.18 |

1.55 |

0.39 |

0.33 |

2.34 |

±0.10 |

14.6 |

|

AWM 1007 80℃ 300V |

|

AWG

No. |

section |

conductor |

insulation |

Wire OD |

conductor resistance 20℃ |

|

structure |

Dia. |

nominal thick |

Mi, n. thick |

nominal |

allowance |

|

mm² |

NO./mm |

mm |

mm |

mm |

mm |

mm |

Ω/KM |

|

32 |

0.0324 |

5/0.10 |

0.3 |

0.74 |

0.66 |

1.77 |

±0.10 |

381 |

|

31 |

0.0401 |

6/0.10 |

0.3 |

0.74 |

0.66 |

1.77 |

±0.10 |

381 |

|

30 |

0.0507 |

7/0.10 |

0.3 |

0.74 |

0.66 |

1.77 |

±0.10 |

381 |

|

29 |

0.0647 |

9/0.10 |

0.35 |

0.74 |

0.66 |

1.82 |

±0.10 |

297 |

|

28 |

0.0804 |

11/0.10 |

0.40 |

0.74 |

0.66 |

1.87 |

±0.10 |

239 |

|

27 |

0.102 |

13/0.10 |

0.43 |

0.74 |

0.66 |

1.90 |

±0.10 |

199 |

|

26 |

0.128 |

7/0.16 |

0.48 |

0.74 |

0.66 |

1.95 |

±0.10 |

188 |

|

25 |

0.162 |

9/0.16 |

0.56 |

0.74 |

0.66 |

2.03 |

±0.10 |

150 |

|

24 |

0.205 |

7/0.20 11/0.16 12/0.15 |

0.60 |

0.74 |

0.66 |

2.07 |

±0.10 |

94.2 |

|

23 |

0.259 |

11/0.18 |

0.70 |

0.74 |

0.66 |

2.17 |

±0.10 |

74.5 |

|

22 |

0.324 |

13/0.18 7/0.25 17/0.15 |

0.75 |

0.74 |

0.66 |

2.22 |

±0.10 |

59.4 |

|

21 |

0.412 |

17/0.18 |

0.88 |

0.74 |

0.66 |

2.35 |

±0.10 |

46.9 |

|

20 |

0.519 |

21/0.18 10/0.254 26/0.16 7/0.31 |

0.96 |

0.74 |

0.66 |

2.43 |

±0.10 |

36.7 |

|

19 |

0.653 |

26/0.18 |

1.10 |

0.74 |

0.66 |

2.58 |

±0.10 |

29.1 |

|

18 |

0.823 |

33/0.18 16/0.254 7/0.39 24/0.20 |

1.20 |

0.74 |

0.66 |

2.68 |

±0.10 |

23.2 |

|

17 |

1.04 |

21/0.254 40/0.18 32/0.20 |

1.38 |

0.74 |

0.66 |

2.86 |

±0.10 |

18.3 |

|

16 |

1.31 |

26/0.254 7/0.49 52/0.18 |

1.55 |

0.74 |

0.66 |

3.03 |

±0.20 |

14.6 |

|

| |

|

| |

|

|

| |

|

Copyright (c) 2010 Orient Star International Group (HK) Ltd.

苏ICP备10063250号 TEL: 852- 211644409 E-mail: wilson2103@163.com

Add:6/F, Hang Pont Commercial Building, 31 Tonkin Street, Cheung Sha Wan, Kowloon, Hong Kong |

|